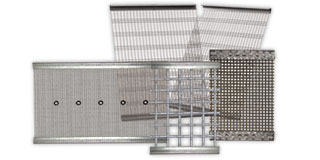

The new Model MR-7 Screener with its compact, highly efficient design is specially engineered for conveyor-type installations. The double deck MR-7 allows materials to be separated from an approximately 1″ opening on the top deck to a separation down to an 1/8″ opening on the bottom screening deck. Please speak to a sales professional for special opening and alternative configurations.

This deck combination with end-tensioned panels provides a screening unit that can effectively handle sand, gravel, crushed stone, coal, slag, topsoil, mulch, ash, recycled asphalt or concrete, and many other industrial-type materials. The MR-7 Screener (48″ W x 84″ L) comes complete with 2 hp, 230/460-volt, 3-Phase, 60-cycle, 1750 RPM motor, V-drive components, and belt guard and conveyor installation carriage members.

The pedestal-mounted MR-7 Screen can be retrofitted with the Midwestern Converta-Screen Heating Transformer to eliminate blinding from damp material. By applying a low voltage current through the screen mesh, the surface tension is broken, so damp material is unable to stick to the wire mesh, thus maintaining higher production rates. The MR-7 can handle wash applications by applying easily adaptable spray bars.

The MR-7 features high load capacity, high screening efficiency, quick setup, and low maintenance. It offers an ideal screening solution for a variety of industries wanting to separate materials for reuse or obtain salable products.