Features & Benefits

The Low-Profile Separator features a flow-through design effective for high capacity screening of dry and wet scalping applications. The compact design allows the Low-Profile unit to easily be incorporated to existing product lines or be placed in “tight-fit” installations.

The two gyrating motors are positioned 180 degrees apart on external, adjustable side motor mounts, maximizing space and screening efficiency. The adjustable motor mounts enable strategic motor positioning, providing the best possible throughput and oversize discharge for a variety of scalping applications.

- Compact size fits confined spaces

- High capacity flow-through design

- Screen wet or dry materials

- Strategic motor placement

- Available in many sizes

The Low-Profile Separator can accommodate high-temperature scalping applications due to the external motor placement. It is also available in many finishes suitable for food, pharmaceutical, dairy, and many more scalping processes.

For more information on the Low-Profile Separator

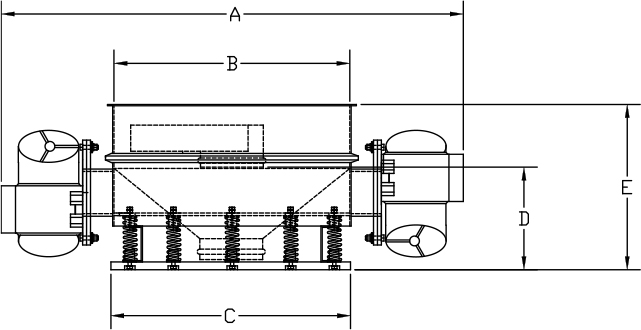

Size Chart

The Low-Profile dimensions above do not reflect any additional items or accessories. Ball trays and covers will alter overall dimensions. A detailed drawing is provided to each customer for individual accuracy.

| Model | A | B | C | D | E |

|---|---|---|---|---|---|

| MLP-24 | 44 1/4″ | 22 1/2″ | 22 7/8″ | 9 3/4″ | 15 3/4″ |

| MLP-30 | 52 1/4″ | 30 1/8″ | 27 3/4″ | 10 1/8″ | 18 1/8″ |

| MLP-48 | 45 3/4″ | 45 3/4″ | 36 3/4″ | 15 3/4″ | 23 3/4″ |

Videos

Low-Profile Separator Videos

Low-Profile Separator Screener

The Midwestern Low-Profile features a flow-through design effective for high capacity screening of dry and wet scalping applications. The compact design allows the Low-Profile unit to easily be incorporated into existing product lines or be placed in “tight-fit” installations.

Instructional Videos

Round Separator Anti-blinding Slider Tray Installation

This video demonstrates how to install a slider tray assembly and screens with a center for a round separator.

Round Separator Anti-blinding Ball Tray Installation

This video demonstrates how to change a ball tray assembly and screens with a center for a round separator.

Changing a Screen With a Center On a Round Separator

This video demonstrates how to change a screen with a center on a round separator.

Change Centerless Screen for a Separator

This video will show you how to change a centerless, round screen in a round separator.

Changing a Clip-in Slider Assembly

This video demonstrates how to change a screen with a clip-in slider assembly commonly found on separators that help eliminate blinding.

Low-Profile Separator Brochure Download Low-Profile Separator Brochure

Low-Profile Separator Brochure Download Low-Profile Separator Brochure