Features & Benefits

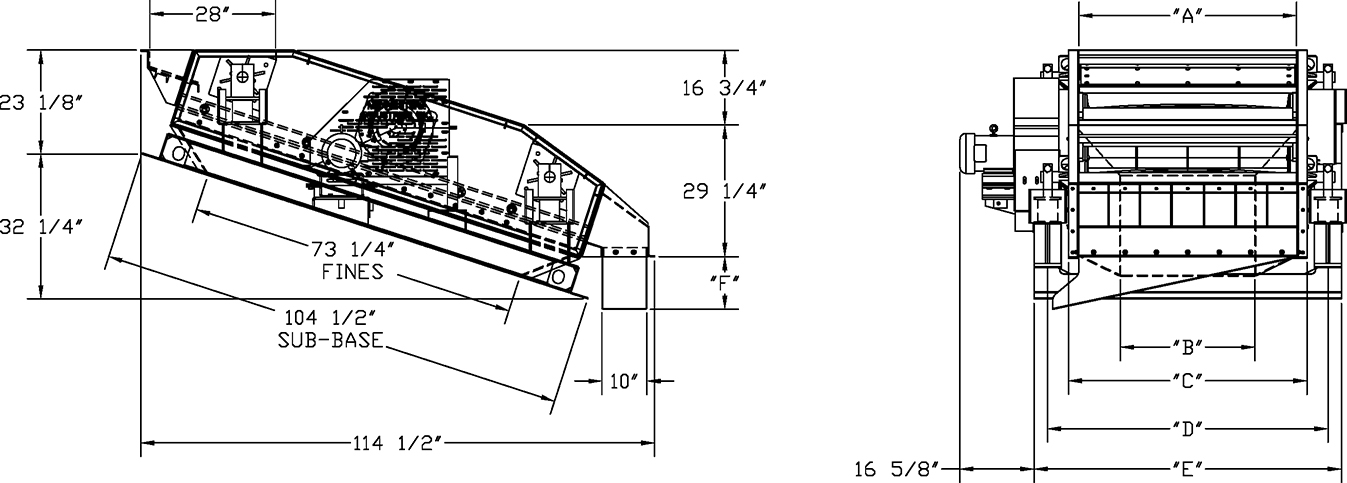

The Midwestern Industries MASP Screener/Scalper is a compact screener that’s designed for high-volume screening of asphalt, aggregate materials, and more. MASP are manufactured in a variety of sizes ranging from 3′ × 8′ to 5′ × 10′ with single or double-deck options. The MASP also offers a deck changing feed option that allows users to switch the feed to either the first or second screening deck on the fly.

The MASP screener/scalper features a heavy duty two bearing vibrating screen, with two selected side-tensioned screen surfaces for product size on a parallel grid deck design. The particle stream is split up on a total of 24 sq. feet of screening area. The unit is to be pedestal mounted and complete with sub-base frame.

The MASP has long-life spherical roller screen bearings and is driven by one 5 H.P., 230/460 Dual Volt, 3-phase, 60 Hz TEFC Motor with motor mount and guard. The feed box is steel lined with replaceable A-R. Complete and self-contained. Less screen panels are needed.

For more information on the MASP Screener

Size Chart

The MASP Screener/Scalper is an ideal screener for asphalt and aggregate applications.

Videos

Instructional Videos

15 Minute Screen Change

Midwestern’s rectangular screening equipment feature end-tension screens that can be changed in just 15 minutes.

Free Test Facility

Midwestern provides our customers with one of the most advanced testing facilities in the screening industry ⎯ FREE of charge.

MASP Screener Brochure Download MASP Screener Brochure

MASP Screener Brochure Download MASP Screener Brochure