Designed to remove solid materials from liquids, Midwestern’s dewatering MEV vibrating screen and stainless steel separators are manufactured to meet your exact specifications and maximize your screening process. Accessories, such as the liquid material distributor and the separator feeder, will ensure the entire screening surface is being utilized to create more efficient screening.

Lightweight and cost-effective, the MEV Dewatering Screener is ideal for applications in the areas of golf course sand, clay slip, coal, magnetite, salt crystals, wood chips, paper pulp, laundry lint, plastics, poultry, and much more. The dewatering screener ranges in area, 15- to 50-square-foot of screening area, and in size, 3′ x 5′, 4′ x 8′, and 5′ x 10′.

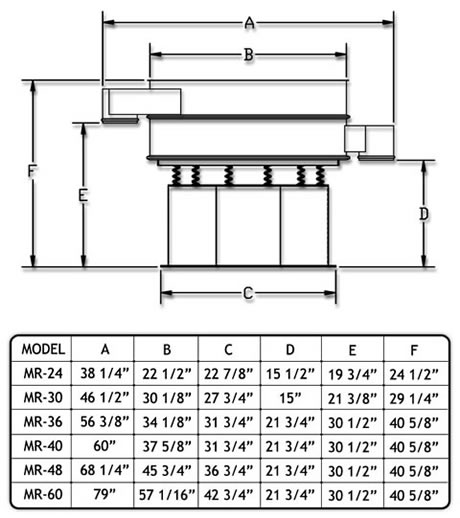

The stainless steel separators have the same capabilities as the rectangular screener with varying throughput rates. Ranging in size from 24 inches to 60 inches, the separator’s footprint is small and may be used in tighter spaces.