Midwestern is a U.S. manufacturer of screening equipment, replacement screens and parts. Easily integrate our equipment into an existing process and gain the reliability and value that you deserve. Midwestern offers: Outstanding customer service, on-time deliveries, custom built screening equipment, and replacement screens and parts for most makes and models of screeners.

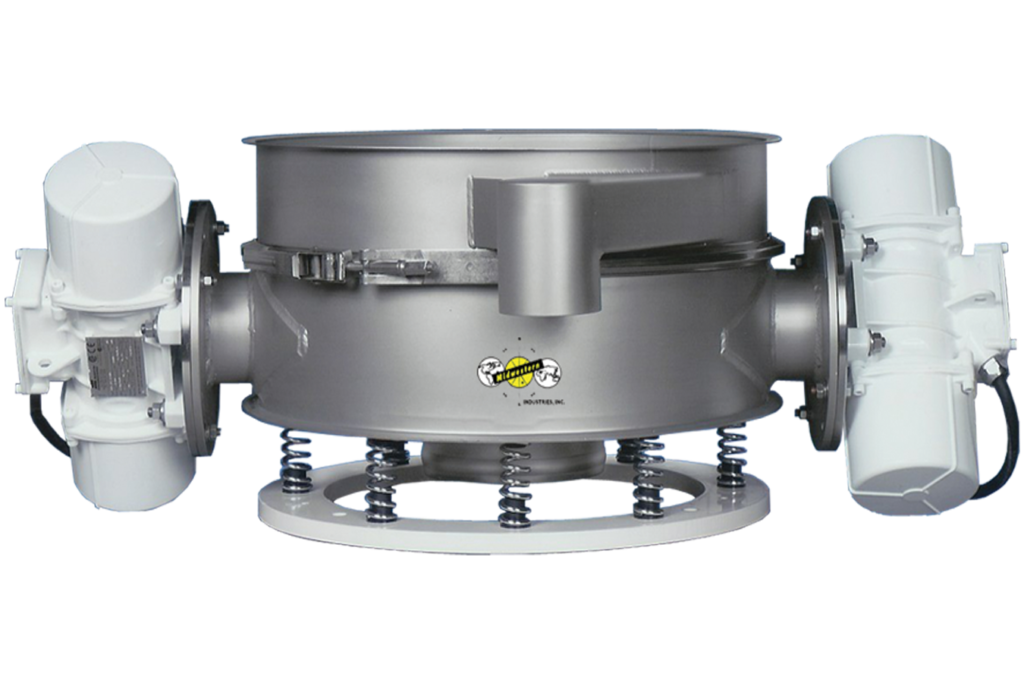

MR Gyra-Vib® Separator

Distinct design features allow the MR Series vibratory separator to produce a consistent and accurate product.

- Wide range of screen meshes

- Available in 3A standard

ME Gyra-Vib® Separator

An adjustable motor mounting system allows for greater product control and minimal maintenance requirements. Precision screening is accomplished by utilizing a unique weight system to manipulate flow patterns.

ME Separator Info

Low-Profile Separator

The low profile separator features a flow-thru design effective for high capacity screening of dry and wet scalping applications.

- Compact size fits confined spaces.

- Strategic motor placement

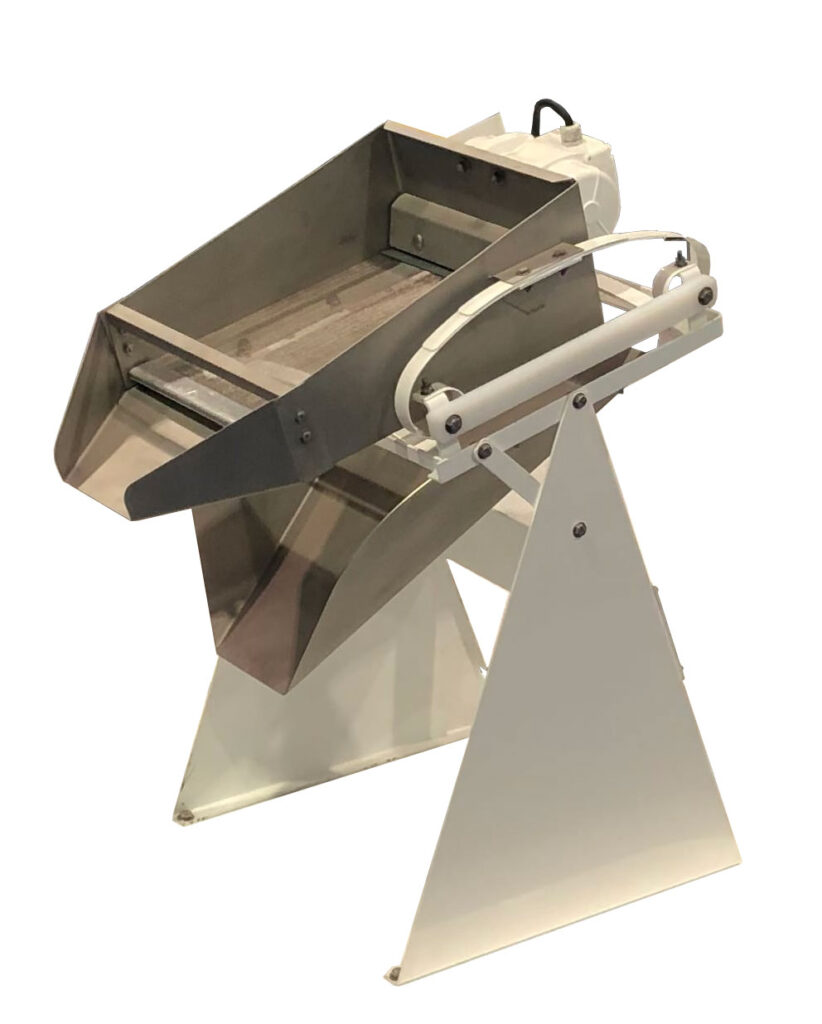

Bag-Dump Station

Quickly examine bagged materials for foreign materials before they enter the manufacturing process. With the low-profile and the flow-thru design, the bag-dump station will easily fit into your screening process.

Bag-Dump Info

Porta-Sifter® Screener

Designed for easy mobility, the Porta Sifter is a great solution for screening materials with minimal oversize.

- Many mounting options

- inexpensive sifting solution

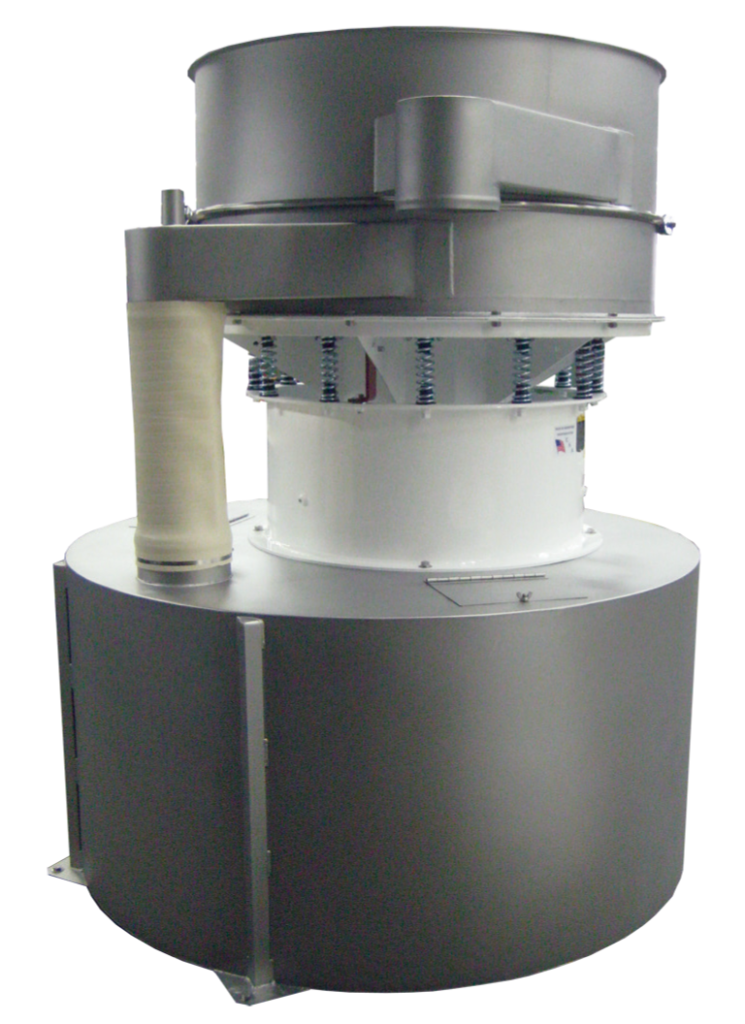

Separator with Stainless Tank

Take advantage of Midwestern’s round separator and stainless steel tank combination to reclaim valuable heat energy from wastewater.

Stainless Tank Info

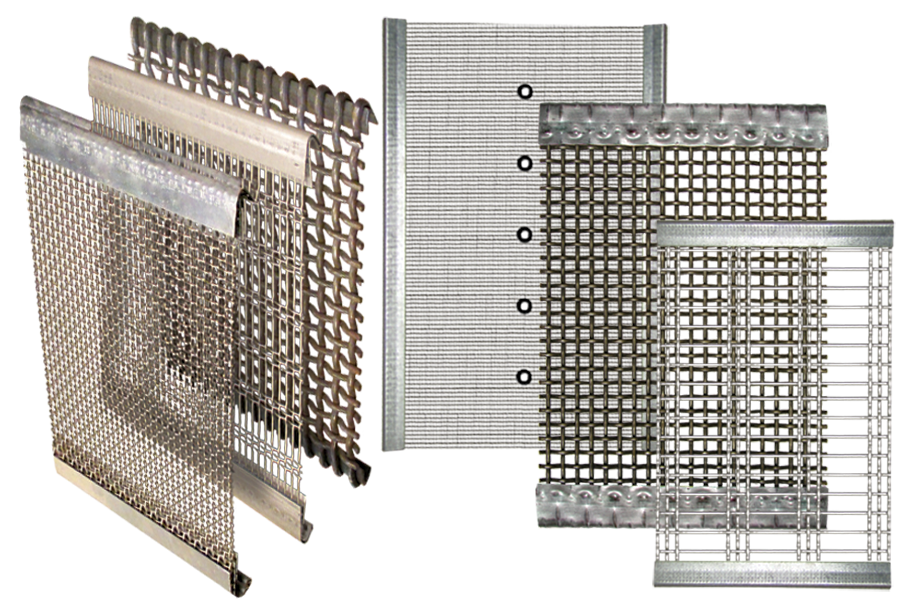

Replacement Screens & Parts

Replacement screens and parts are available for most makes and models of screeners, speak to a sales associate to discuss your screening needs.

- Competitive pricing

- On-time delivery

MEV® Screener

This versatile screener comes in a variety of sizes to accommodate your screening application.

- 1 to 5 screening decks available

- Quick screen changes

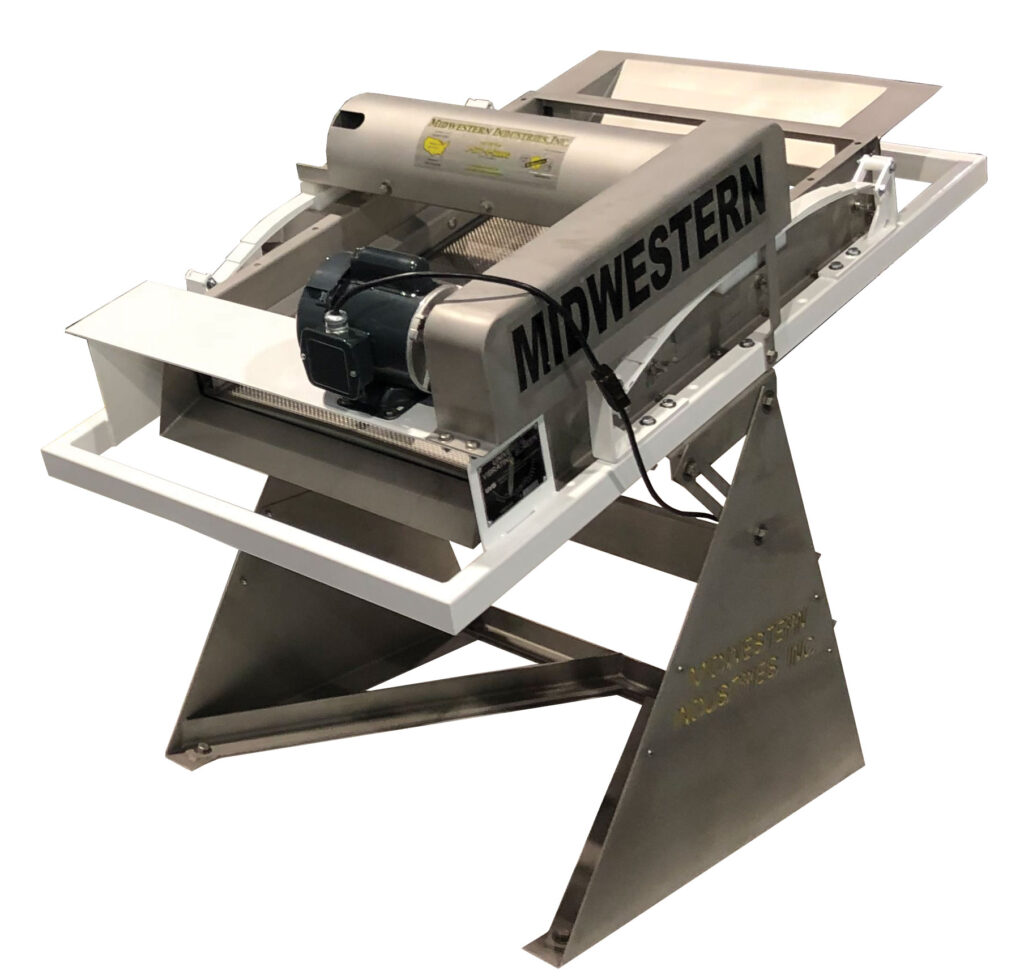

Multi-Vib® Screener

Two counter-rotating motors create a lineal motion perfect for screening fine material at a higher production rate. End-tensioned screens make for easy and quick screen changes.

Multi-Vib® Info

MR-7 Conveyor Screener

Highly-efficient design is specially engineered for conveyor-type installations with end-tensioned panels that can be changed in just minutes.

MR-7 Screener Info

Universal Screener

The Universal screener is a great way to screen a multitude of wet, damp, dry or sticky materials and dewatering applications.

- Rugged construction and compact design

Uni-Rod® Screening Machine

The self-cleaning Uni-Rod with two-decks provides high hourly output and low machine downtime.

Uni-Rod Info

MASP Screener/Scalper

A compact screener that’s designed for high-volume screening of asphalt, aggregate materials, and more.

MASP Info

Uniflex Screener

Available in single or double deck models, the Uniflex is ideal for continuous or batch screening.

- Many mounting options

- Inexpensive sifting solution

Univibe Screener

Designed for easy mobility, the Univibe is a great solution for screening materials with minimal oversize.

- Two models available

- Easily Portable

Ultra-Vib Screening Machine

The Ultra-Vib is designed for liquid/solid separating applications able to handle high volume.

Ultra-Vib Info

Custom Wire Mesh

Replacement screens are available for most makes and models of screeners.

- Competitive pricing

- On-time delivery

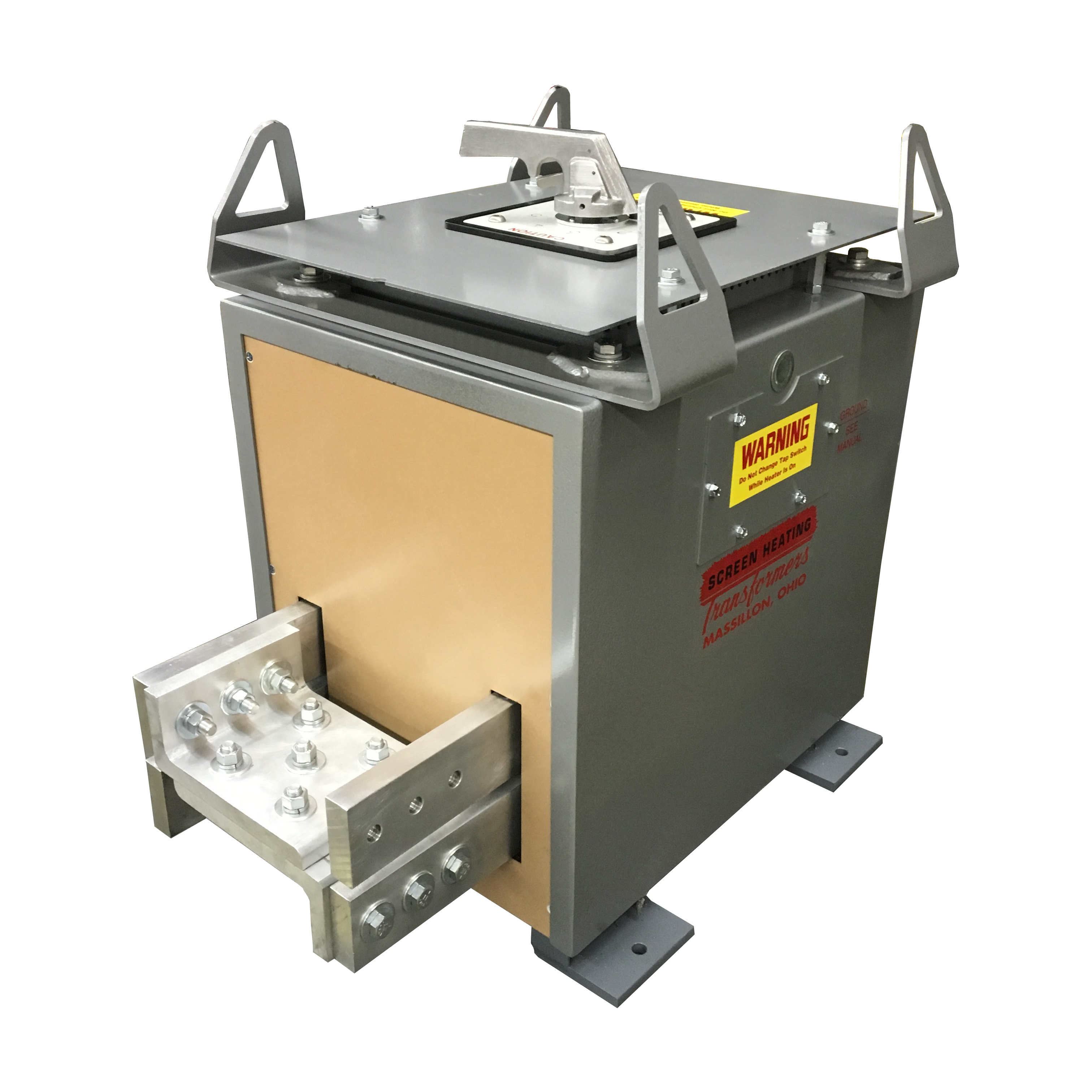

Screen Heating Transformer

Safely reduce moisture induced blinding on screening surfaces with a low-voltage transformer. The unit can be retro-fitted to many other makes and models for better screening.

Screen Heating Info