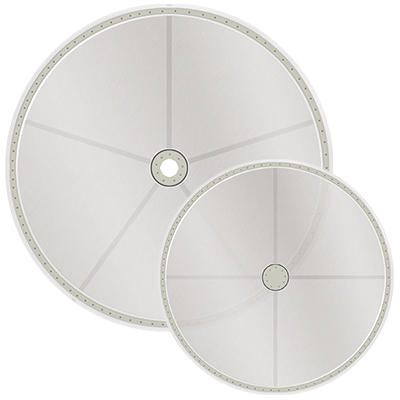

Available for Most Makes and Models

Midwestern recognizes your need for one supplier to offer a wide variety of screens and parts for all your round vibratory separators ⎯ regardless of make or model. We work with our customers to ensure Midwestern offers the type of screens you want in the sizes you need.

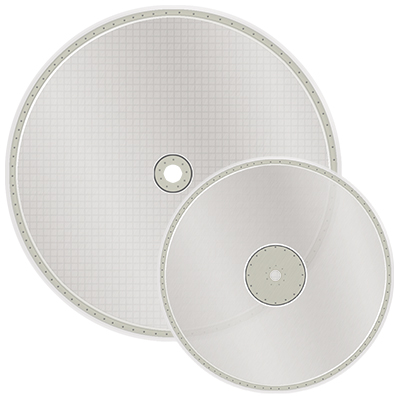

Replacement Screens for Separators

Sizes range from 18 to 72 inches and can fit nearly every make and model of separators with various mounting methods – including strict food grade standards.

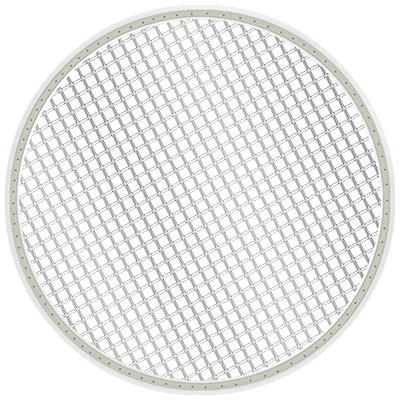

Clear Opening Screens

Midwestern offers clear opening screens and custom weaves not shown on our mesh chart. Speak to a sales professional for options and availability.

Ultrasonic Screens

In a constant effort to supply our customers with innovative screening options, we offer ultrasonic screens for various makes and models. Rescreening is also available.

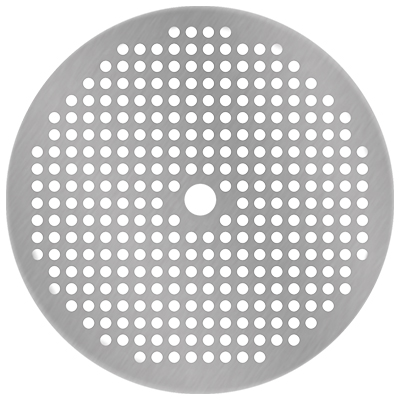

Perforated Screens

Customized to meet your screening needs, our perforated screens come in a wide range of sizes and are available with round and slotted openings.

Sandwich Screens

Plastic sliders or rubber balls are sandwiched between a sizing screen and the backup mesh, providing added vibration dislodging near size particles and allowing material to flow more efficiently.

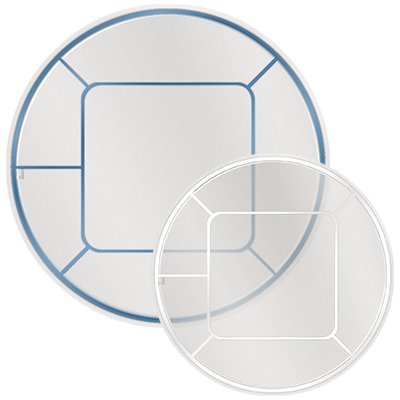

Bulls-Eye Screens

Applying silicone beads in a bulls-eye pattern between the sizing screen and backup mesh reduces friction while extending the life and performance of the screen.

Wagon Wheel Screens

Dense material on fine mesh screens and larger diameter screens can benefit from the added support provided by the wagon wheel design. These can be made to fit most makes and models of separators.

Custom Screen Options

As a manufacturer, not a reseller, Midwestern works with our customers to provide customized screening solutions. From nylon mesh to “white wall” screens, we supply unconventional screens for your application. Speak to a sales professional for options.