This vibratory separator utilizes an adjustable motor mounting system that allows for greater product control and minimal maintenance requirements. The screening machine will screen material as fine as 25 microns and is available from 24 to 72 inches.

ME Series Separators use a standard NEMA foot-mounted motor. Explosion proof motors can be used for hazardous locations and can be supplied in any voltage requirement.

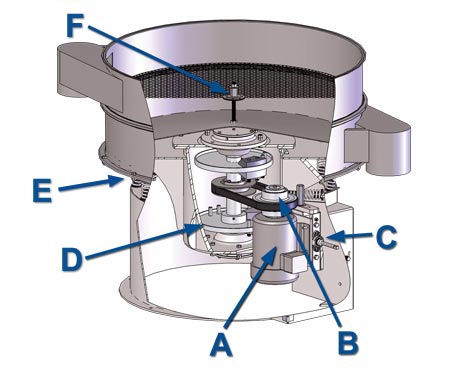

The variable speed pulley is easily accessible and mounted on the motor, isolating the screen vibration from the motor. The motor is mounted on an adjustable motor slide base, allowing for a variable speed range of 950 to 1450 RPMs.

The slide base is adjustable for the control of frequency. Power is transmitted from the motor to the balance cages using a variable speed belt.

Balance cages are mounted on a large diameter shaft between standard, heavy-duty, double spherical roller bearings. Specially designed bearing housings have greater grease capacity for long life as well as convenient lubrication fittings.

For increased durability, the unit’s base and table assemblies are constructed of heavy steel plate by certified welders. The lower frame is bolted to the table on 36″ through 72″ diameter units, enabling the use of multiple screening surfaces without turning of the spacing frames. Carbon steel and stainless steel (types 304 and 316) are furnished for surfaces in contact with product flow. Abrasion- and corrosion-resistant coatings are also available. Decks and discharge features may be modified to fit screening requirements. The use of “V” type clamp rings permits easy, quick changing of replacement screens.

The reversible center locking devices allow positive screen tensioning, up or down.

ME Separator Brochure

Download Midwestern’s brochure for the ME Series Gyra-Vib® Separator.

Download Brochure

Free Test Facility

To better serve our customers, Midwestern offers our full-scale test facility free of charge.

More Information

Auto-CAD & Dimensions

Midwestern offers our separators in sizes ranging from 24 to 72-inch in diameter. We provide single deck dimensions for your convenience.

This video will show you step-by-step how to change a screen with a center hole with particular focus on the proper procedures of both taking off an existing screen and replacing it with a new one.

This video demonstrates how to change a screen with a clip-in slider assembly commonly found on separators that help eliminate blinding.

Midwestern’s commitment to providing our customers with outstanding screening products continues with our full line of replacement round screens. Our screens are manufactured to fit all makes and models of round vibratory screeners.