The Vibratory Separator is a cost-effective solution to your screening process. Each round separator is built individually to suit your screening needs. Whether it’s ultrafine powders or liquid/solid separation, the MR Series Round Separator can produce the results you’re after.

Available with specially designed 1200 RPM motors. High-speed 1800 RPM motors are also available for applications that require screening solids from a large volume of heavy, high-viscosity liquids.

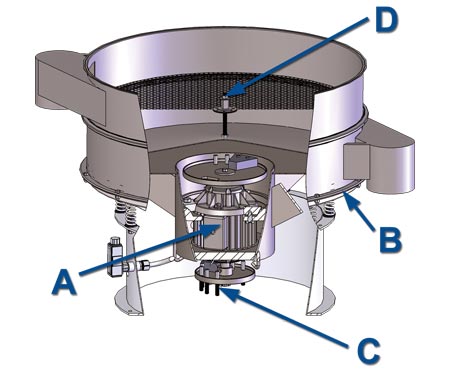

Bolt-mounted lower frames will not turn and wear out the flanges on the table and lower frame. A conversion kit is available to modify an existing conventional clamp-mounted separator lower frame to the bolt-mounted style.

Balance cages, designed for quick weight adjustments, can be mounted directly on the motor shaft.

Reversible center locking devices allow positive screen tensioning, up or down.

MR Separator Brochure

Download Midwestern’s brochure for the MR Series Gyra-Vib® Separator.

Download Brochure

Free Test Facility

To better serve our customers, Midwestern offers our full-scale test facility free of charge.

More Information

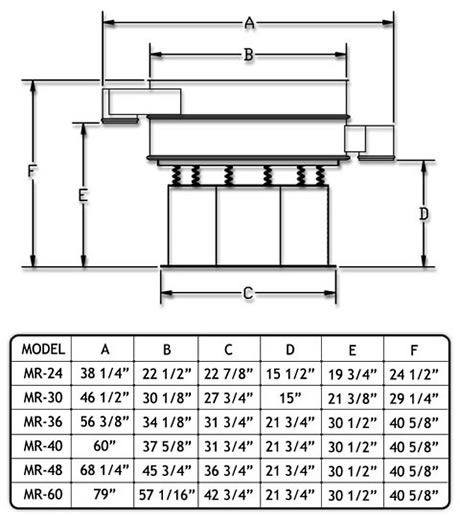

Auto-CAD & Dimensions

Midwestern offers our separators in sizes ranging from 24 to 72-inch in diameter. We provide single deck dimensions for your convenience.

This video will show you step-by-step how to change a screen with a center hole with particular focus on the proper procedures of both taking off an existing screen and replacing it with a new one.

This video demonstrates how to change a screen with a clip-in slider assembly commonly found on separators that help eliminate blinding.

Midwestern’s commitment to providing our customers with outstanding screening products continues with our full line of replacement round screens. Our screens are manufactured to fit all makes and models of round vibratory screeners.