Features & Benefits

Reduce screen blinding due to wet or damp material by adding a Screen Heating Transformer. The system can be added to an existing Midwestern High-Frequency Screener or retrofitted to most other makes and models. This simple and effective way to eliminate blinding is a cost-effective way to maintain higher production rates.

Screening efficiency is often affected by wet weather or moisture in the material being processed. The particles begin to build up on the wire cloth screens, hampering production and plugging or blinding the screens. Clearing the screen mesh with hammers, brooms, chains, torches, etc. can cause expensive damage and lost production time.

Midwestern’s low-voltage Converta-Screen Heating System helps to reduce or eliminate this problem by sending a safe low-voltage current through the wire cloth screens. The damp particles will not adhere to the warm wire, keeping the screen open and allowing material to pass through.

The Converta-Screen Heating System is safe and shockproof. All exposed conductors carry only as much voltage as a toy electric train. Screen changes are done quickly because electrical connections and insulation are not disturbed. Only the screen tension bolts are removed, just as on unheated screens.

Before and After

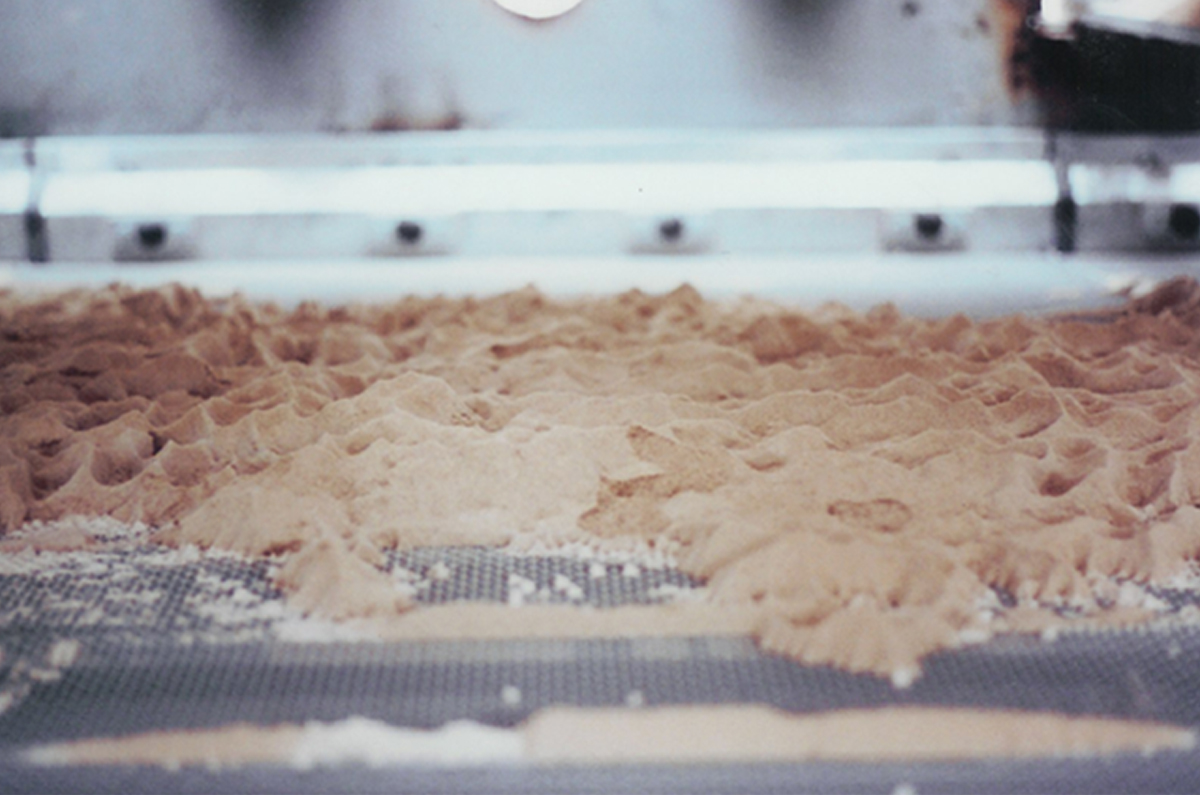

Before Screen Heating

The damp material is plugging up the screening surface by adhering to the wire mesh, reducing the efficiency, capacity, and overall performance of the screener.

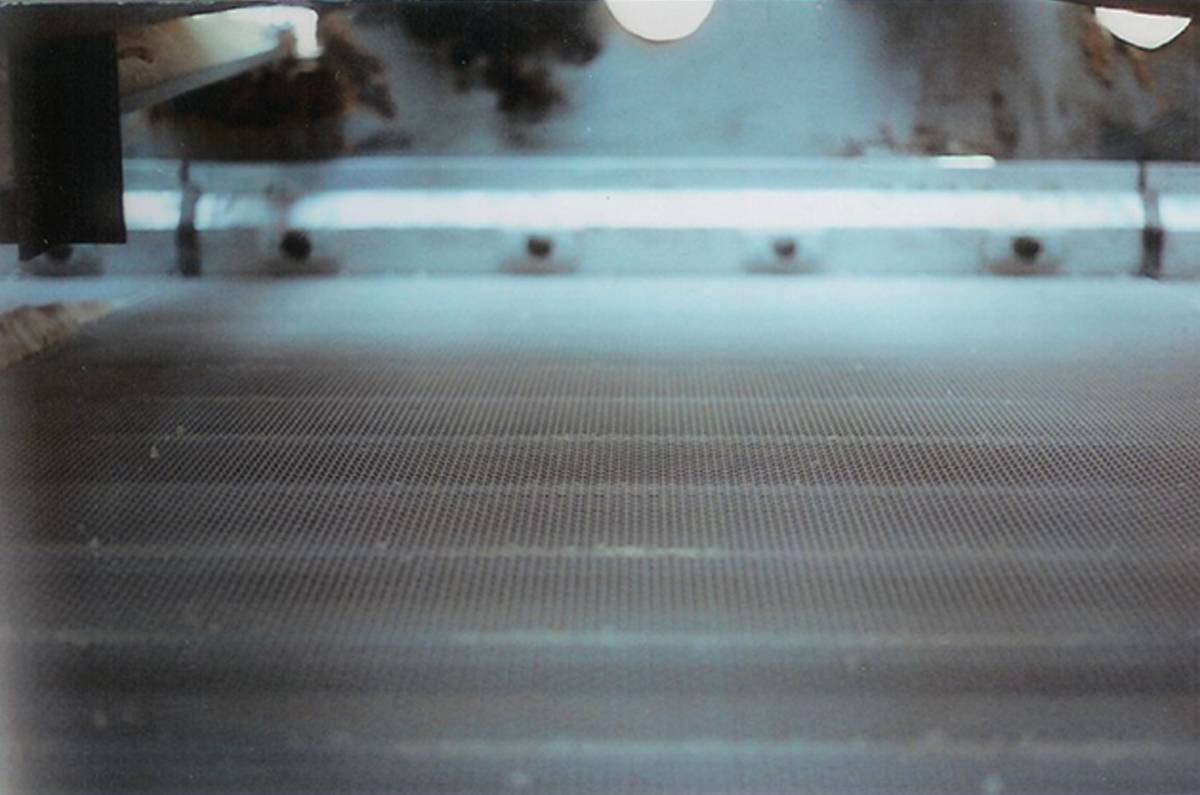

After Screen Heating

By applying a low-voltage current through the screen mesh, the surface tension is broken and the damp material is unable to stick to the wire mesh.

Videos

Converta-Screen® Heating Videos

Converta-Screen® Heating

Discover how Midwestern Industries’ Converta-Screen® Heating can help you get more production when screening damp or sticky materials.

Converta-Screen® Heating Brochure Download Converta-Screen® Heating Brochure

Converta-Screen® Heating Brochure Download Converta-Screen® Heating Brochure