The separator along with the tank can be manufactured in a variety of sizes to fit your processing needs. Either the ME Series or MR Series Separator can be used in this type of application. Midwestern’s experienced staff is available to determine the proper equipment to meet your screening needs.

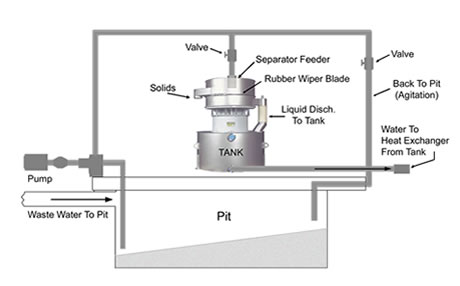

The pit’s sloping bottom directs fibers and solids to the low corner from where it is then pumped to the separator. Water that goes to the screen passes through a separator feeder, reducing splashing and allowing for aeration. Screened wastewater is discharged into the stainless steel tank, and then pumped to a heat exchanger where incoming cold water is heated.